The distinction between industrial-grade and consumer level USB products goes deeper than just designing to meet the needs of specific applications.

You’ve probably encountered both industrial-grade and consumer level USB products. Choosing the wrong one can lead to serious complications from device breakdowns to budget failures. It’s essential that industrial settings incorporate USB hardware that’s up to the task of the harsh realities of their application and environments. Doing so will save you time, money and headaches, propelling you forward more efficiently.

Coolgear’s approach to the USB interface is holistic – we see the big picture and know where we fit in. Engineers, designers, integrators, innovators, they all work this way too. That’s why we stress over every detail from the testing lab, to build quality, and then back again to the lab to improve, refine, and polish over and over, resulting in industrial-grade products that are as durable as they are sophisticated.

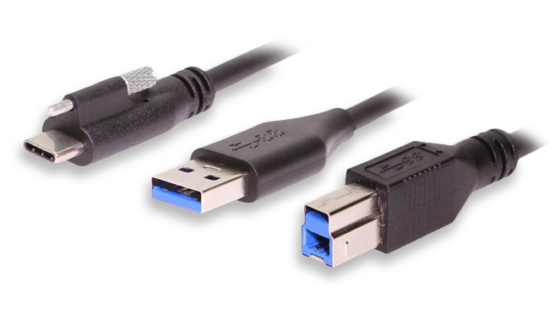

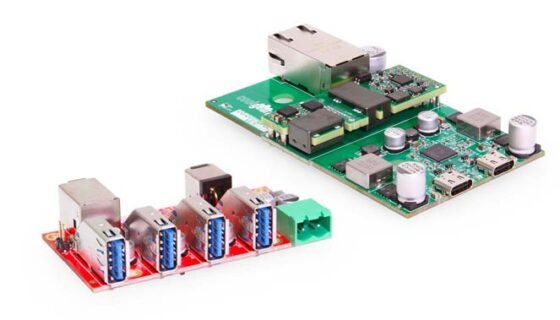

Build Quality is often first on our minds. It has got to hold everything together in environments with high levels of shock and vibration. We design and construct USB hubs, chargers, serial devices, adapters, and cables with the harsh reality and demands of industrial life in mind.

From the durable metal shells that we wrap our hubs in, to the dependable controllers, firmware, and flash chips that we are integrating, we’re confident in the rugged quality of our product.

Customers in need of industrial-grade USB demand high performance to meet the stresses of harsh industrial environments, such as in labs, warehouses, heavy machinery, and automation equipment. So, we constantly challenging ourselves to build USB components that are far tougher than consumer level USB, and sturdier than anything that came before.

Testing plays an essential role in our approach because we don’t just flip the switch on and off a couple times and pack it up. Oh no—we’re in it for the long haul. We run our products through rigorous tests, observing and refining as we go. With all this extensive testing of our USB products in our Coolgear Labs comes our word.

Our products are guaranteed not to fail under extreme conditions.

From medical device chargers in ambulances, to GPS connectivity in firetrucks, to USB hubs for heavy payload robotics and more. We make USB hardware with serious reliability for serious people who are working in serious environments. The results are factory ready, with ESD Surge Protection, wide temperature operating temperature ranges, and diverse mounting options.

Compatibility is essential as our clients seek specialized USB products that meet their specific technical needs while meeting other high performance benchmarks.

From the newest innovations to the vast ecosystem of legacy devices you may have to integrate into your technology, to a variety of mounting options like DIN rail, wrack, and surface or wall mounting, we can ensure that your USB hubs are integrated into your industrial environments, protecting your equipment and functioning seamlessly.

Power sets industrial-grade far apart from commercial USB hubs. Our USB hubs can be designed, built and tested to meet almost any specification. Need to charge 50 high current devices at once with built-in protections from overdraws and surges? Sure. Why not. We can make it for you.

From custom power solutions to engineering our own integrated circuit chip to work with USB Type-C power delivery outputs that was 60% smaller than any other PoE to USB-C solutions at the time, we design industrial-grade USB hubs with more power and flexibility.

With greater power demands also comes greater engineering challenges and we’ve designed our entire lab around building and testing USB hubs that stand up to these challenges in basically any environment.

Support is where we round out our industrial approach.

When you need custom solutions to tough problems we roll up our sleeves and get to work in the Coolear Labs. We think this is where we really shine.

We built a team of dedicated professionals who have experience across multiple industries including Automotive, Kiosk, Workstation, Industrial, Medical, and Robotics.

We’ve developed our processes specifically around industrial and commercial use. Engineers and integrators are our people and we want to help them achieve excellent designs and innovative systems for the future.