The huge variety of legacy devices that use the serial communication system, which includes RS232, RS422, and RS485 products, is vast and vital. It’s important to understand why. RS232 was once the most popular and high-tech protocol available. It grew to become, for decades, the most widely employed standard globally. Today, it’s easy to work in the field and come across this protocol rather infrequently. USB has largely replaced older serial data communication protocols like RS232. Yet, these older serial communication protocols, including RS422 and RS485, are still around and still quite useful under certain scenarios and conditions, especially in industrial applications where legacy devices are common and sometimes have their advantages over USB, but must now be made compatible with USB devices.

RS232: The OG of the Modern Communication Protocol

First introduced in 1960, RS232 was soon after defined by the Electronics Industries Association, or EIA, as a way to standardize communications between devices. RS stands for “Recommended Standard,” though not all RS232 devices use exactly the same specifications, as the standard has been updated over the decades. For example, some devices use a 25-pin D point connector, versus the more common 9-pin D point connector.

RS232 is well regarded for its extreme simplicity and relatively low cost. It is very common in legacy devices. And in point-to-point applications, where simplicity is ideal, like with some industrial control equipment, it is still sometimes favored. Additionally, cables of up to 50 feet can be supported by RS232, though maximum length depends upon capacitance. RS232 also handles noise better than many other protocols.

Just as other programming languages have largely disappeared over the years while still being found in use in millions of legacy applications (and sometimes new ones as well when conditions are right), RS232 has stuck around, and not in spite of its lack of virtues, but because of its many virtues.

One can still find new or developing data communication projects that are currently implementing serial communication protocols and devices because they can be more cost-effective, simpler to implement, and more flexible under many conditions.

The Evolution of Serial Communication: RS422 & RS485

As technology advanced, the RS232 standard began to show signs of being overburdened with faster and faster communications speeds. As its speed limitations and reliability began to be pushed to its limit, RS422 was created, implementing more sophisticated wiring that was more balanced and more resilient to electromagnetic interference. This means that RS422 could be wired at dramatically longer distances, up to 4,000 feet, and could perform at faster speeds. 100 kbps is common, and at shorter distances 10 Mbps was possible. These specifications still make sense for many engineers today, which is why RS422 can still be found being implemented in new projects.

RS485: The Industrial Cousin of Serial Communication Protocols

RS485 was the next iteration of the serial RS- communication standard. Developed for industrial applications in which many different devices needed to be systematically connected, it is effective when used in digital multipoint systems, commonly handling up to 32 drivers and 32 receivers. It is still frequently found in industrial telecom and other computer and automation system settings, such as motor drivers, video surveillance, base stations, robotics, and even home appliances. RS485 is also used for data transmission between controllers and disk drives in computer systems, and, perhaps most popularly for RS485, it is used in programmable logic controllers in factory floors where electrical noise is high. All of this makes RS485 a valuable and still quite relevant network standard in technical industrial applications, and even in some consumer settings.

Serial Communication Protocols Are Still Relevant

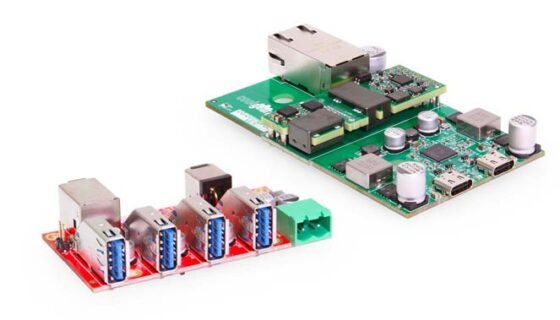

Over the years a vast variety of complementary serial communication standards with high speeds, reliability, adaptability, and affordability have become important, especially in industrial settings. Hybrid applications such as serial over ethernet and USB to serial communication, of which Coolgear has dozens of high-quality options, designed for harsh industrial use, are great options for integrating the new with the old. By incorporation legacy and modern data methods, increased flexibility, savings, and better solutions are arrived at.